Spindle Actuated Hydraulics (S.A.H.)

Kirsan Engineering's Spindle Actuated Hydraulics (S.A.H.) eliminates human error and the requirement of an external hydraulic source. This design eliminates the need to hydraulically couple, actuate, monitor pressures, and un-couple during loading and unloading of parts onto your fixtures. The S.A.H. units will give you peace of mind knowing that your fixture is fully charged and your parts are clamped at the same pressure each and every time.

Has any of the following ever happened in your shop?

- Forget to power up the fixture before it moves into the machine

- Forget to close or open the valve while activating the external pump

- Forget to remove the hydraulic hose from the fixture before it moves into the machine

- Your hydraulic coupler fails or leaks

- Not running the hydraulic pressure up high enough and having your parts move

- Run the hydraulic pressure to high and distort your part

All of these thing have happened at our shop at one time or another and that is why Kirsan designed and manufactured the S.A.H.

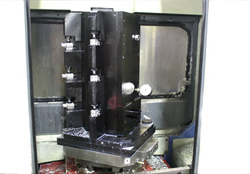

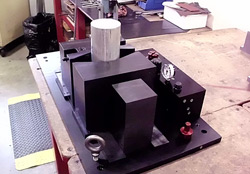

The S.A.H. unit houses a hydraulic pump, valves and reservoir which eliminates the need for any external hydraulic power supply. This eliminates the need to rely on the machinist to connect hoses, de-pressurize, activate pumps or valves. During your machining cycle, with the first tool, a special driver (supplied by Kirsan) is used to engage the S.A.H. and activate the system. Then you tool change and proceed with your machining cycle. At the end of your machining cycle you tool change back and release the hydraulic pressure. Actuating and releasing the pressure does increase your part cycle by (7– 9) seconds. This small cycle time increase is far out weighted by the elimination of errors/problems the S.A.H. unit affords you.

There are two design options with the S.A.H. First, we can design a system that is dedicated to one particular part or family of parts. Or, we can design a system that has removable fixture plates. This allows for more flexibility with regards to the number of different parts you can machine on the S.A.H.’s. With this second option, fixture plates are connected to the S.A.H.’s via a quick change system that simultaneously makes the hydraulic coupler connection, which reduces your time to change fixture plates and drastically reduces the cost of your workholding.

You can design and build your own fixture plates to accommodate your parts, or Kirsan can custom design and build them for you. With no external hydraulic reservoir, pump, or hoses to deal with, your employees and/or robotics are freed from having to connect and disconnect hoses, open and close valves, and pressurize and depressurize the system — eliminating these external devises shortens your load/un-load times and eliminates the possibility of error. No modification to your CNC machines is required, and we offer 2-, 3-, and 4- sided configurations for horizontal applications. The S.A.H’s units can be utilized for vertical applications or virtually any clamping requirement.

For an extra cost, your S.A.H. unit and machine can be integrated with a pressure monitoring system with an auto-shutdown feature to halt the machine if pressure drops below a pre-set safety level.

The S.A.H. units really shine when combined with robotic operations, this system offers measurable productivity advantages above and beyond traditional fixturing systems. Please watch our video for more details. Contact us today for more information and/or a quotation.

Image Gallery

Printable Page

Printable Page  Email This Page

Email This Page